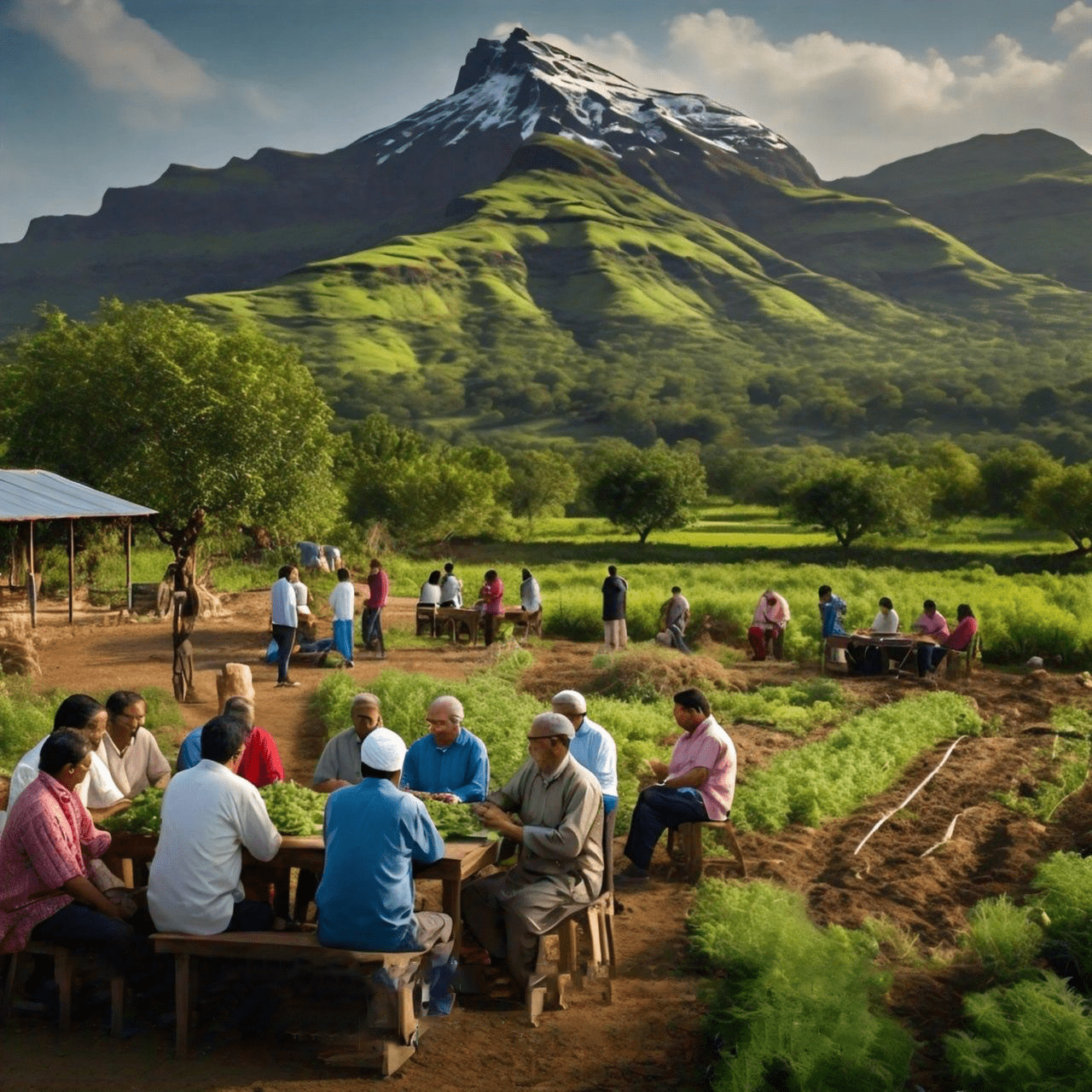

Welcome to Kalsubai Purest, a humble company with a grand vision to revolutionize the world of farming, distribution, and supply chain. Our journey has been one of dedication, innovation, and a deep commitment to providing pure and wholesome food for all. Kalsubai Purest emerged from a simple yet powerful idea – the belief that everyone deserves access to pure, untainted food. With this mission at our core, we embarked on a journey that spanned several years, weaving a new ecosystem that empowers farmers with knowledge, embraces sustainable practices, and ensures a transparent and ethical supply chain.